Copper Foil for Dummies

Wiki Article

10 Easy Facts About Copper Foil Shown

Table of ContentsThe Facts About Copper Foil RevealedIndicators on Copper Foil You Need To Know5 Easy Facts About Copper Foil DescribedThe Best Strategy To Use For Copper FoilFacts About Copper Foil UncoveredA Biased View of Copper FoilFascination About Copper Foil6 Easy Facts About Copper Foil DescribedA Biased View of Copper Foil

When you copper aluminum foil discolored glass great deals of concerns come up that you weren't taught just how to deal with. Scroll down to find a whole checklist of answers to help improve your discolored glass copper foiling.If you aim for the copper foil you'll be place on. 3/16" 1/4" aluminum foil functions well for most common copper foil stained glass pieces.

6 Simple Techniques For Copper Foil

More About Copper Foil

The rolls fit flawlessly as well as when the cover is protected in place, it helps keep the aluminum foil. Beginning hindering far from the perimeter of an item When you copper foil discolored glass it's finest to begin foiling away from the outdoors side as this makes for more powerful bond. This is due to the fact that the foil isn't signed up with on the outdoors side where is is extra likely to find loose.

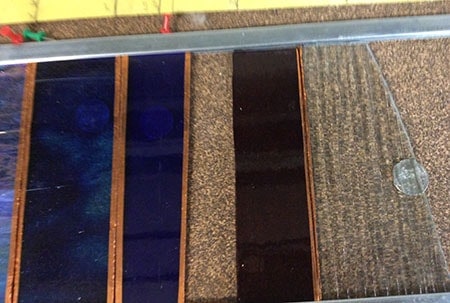

Do you understand exactly how to copper foil discolored glass that is heavily textured? If you've tried this you'll recognize that the aluminum foil breaks as you attempt to go from high to low. Also with superficial textured glass (ripples) the foil in some cases breaks as it crosses the ripples rather than nicely contouring to it.

What Does Copper Foil Do?

Utilize a cork for kinking distinctive glass as it is softer and also offers pressure while lowering tearing. A rubber eraser on the end of a pencil. It cleans the foil also! This functions for croc glass along with various other highly distinctive glass. Turn the glass through the grinder at an angle of 30-45 degrees, flip it and also do the exact same to the opposite side.Better still, you can use a to get rid of the heavy structure on the glass prior to foiling. This truly aids with foil attachment. Before you acquire a rippled bit ensure it will fit your grinder. Use lined paper Extra resources to assist centre the copper aluminum foil When you copper foil discolored glass by hand it can be hard to centre the aluminum foil.

The Best Strategy To Use For Copper Foil

Usage lined paper as a find out here now guide! This is a fascinating question and also one I get asked A LOT. My solution could save you HOURS of time grinding and cleansing. When you copper aluminum foil discolored glass you do not have to have a harsh surface for the aluminum foil to stay with.You can simply weaken the sharp sides off with a wet scythe stone to prevent cutting yourself and to protect against sharp sides reducing the foil. Sometimes when you copper aluminum foil stained glass the foil comes away from the edge.

The 8-Second Trick For Copper Foil

If you solder too gradually or review the solder repetitively the aluminum foil glue melts and ends up being unstuck. It's worth keeping in mind that the adhesive is there to hold the foil in position until it's soldered. It does not offer to keep it on once it's been warmed. Try raising the size of the outside foil a little bit also.

If you tin the sides rather than producing a beaded edge. "Tinning" indicates covering them with a slim coating of solder. "Beading" is a rounded side of solder that 'clings' to the side of the stained glass as well as is much more powerful.

Wiring demand is among the most vital motorists for digital plan selection. The Semiconductor Industry Association (SIA) (Sematech) publishes a record often to advise the industry of the here and now and future circuitry demand for a variety of product types. Table 1 reveals components of the table that was released in 1999 (copper foil).

The Only Guide for Copper Foil

Lower I/O are in hand held items that jeopardize on performance to accomplish their smaller sized size. These I/O worths are leading side applications with the biggest number of I/Os. Typical applications have much reduced demand but over time will certainly reach the leading side demands, which are 510 years in advance of the typical item.This only happens in restricted styles. The various other piece of the I/O Full Article formula is the size of the chip. This is mostly a function of exactly how numerous circuits are being used by the application. In Table 2, SIA (Sematech 1999) has actually specified chip size as a function of the kind of application. copper foil.

Some Of Copper Foil

In this approach, a gold or light weight aluminum cable is bonded to a pad on the chip and then looped to a pad on the chip service provider, which is the base for the component. A common chip to substrate connection utilizing cable bond is noted in Fig. 1. With distinct cables, their positioning can not be also close or the wires will touch each other.Report this wiki page